A step by step Nikon 50mm Repair Guide f1.8 AiS with notes on managing the Series E version of the lens.

Copyright 2022 High5Cameras, Free to use, copy and distribute so long as no charge is made for use, distribution or access and authorship and web address is freely acknowledged.

The Nikon 50mm f1.8 AiS lens is almost identical to the late model Series E lens. Some of its cosmetics are slightly different but it uses almost identical construction. I have made notes through this guide to point out any major differences between the AiS and the Series ‘E’ version so this guide will help you manage either version.

You can see from the images above the second version 50mm f1.8 Series ‘E’ and the AiS version appear almost identical. The cosmetic difference is basically the focus barrel is slightly longer on the AiS with a slightly different grip pattern and the aperture control ring is also slightly longer with a bigger separation between the F stop markings on the lens and the repeater markings for the cameras Judas Window for aperture display in the viewfinder.

The Series E was a low cost version of the AiS for Nikons consumer cameras. The AiS version has better coatings but either lens will return superbly sharp results.

When new and in production the Series E was significantly cheaper than the AiS but internet hype has promoted the Series E version to such an extent that its now almost the same price as the AiS version on the used market.

Nikon 50mm Repair Guide – NOTES BEFORE YOU START

The Nikon AiS 50mm f1.8 is a bit of a challenge. It’s nowhere near as tough as some lenses but it does have some booby traps to catch the unwary.

If you have read my guides on Minolta lenses you will know that Minoltas are usually very kind to beginners and you can afford to not worry too much about helicoil distances. That’s absolutely NOT true with this lens and you need to mark alignment points on EVERYTHING unless you want to spend the next 2 weekends reworking it!

The lens used for this Nikon 50mm Repair Guide was not in a good state. Focus was very stiff due to the oils evaporating inside the lens. This had led to haze on the glass and a very stiff focus. This is very common with these lenses especially if bought off places like eBay where sellers are generally clueless. The Series E that was done in tandem with this lens was even worse with a flakey aperture control, hazed glass and almost no lubricants left on the helicoils giving the lens a sloppy and rattly feel.

Nikon 50mm Repair Guide – NOTES ON WORKING WITH THESE LENSES

Nikon are swinish at applying threadlock so an absolute must for this lens (and any others to be honest) is a decent set of JIS screwdrivers. Philips drivers can be totally relied on to round out screw heads on most Japanese gear and it’s a near certain result when working with Nikon lenses. If you hit a stuck screw apply some Isoprop or Acetone and wait, if its still stuck apply a bit more and wait. Last resort is heat as you will see with this lens. Brute force is seldom a good thing with this lens.

You can use acetone sparingly but be VERY CAREFUL – the lens is mostly plastic and acetone can melt the lens parts as well as the threadlock.

Remember – There is no such thing as luck in repairing optical equipment, if you do it right, using skill and patience you will be rewarded with a perfectly operating lens. A rushed or bodged job will result in the lens being devalued, unpleasant to use and possibly unusable so…..take your time, get the right tools and materials, don’t take shortcuts or advice from people who know less than you (check out my camera history here).

The biggest issue with the 50mm f1.8 AiS is the very tricky focus helicoil distances. I have made lots of notes throughout the this Nikon 50mm Repair Guide so make sure you read the entire guide before starting work.

You will need the following tools and parts to action this Guide

Nikon 50mm Repair Guide f1.8 AiS – Disassembly

First step is to remove the beauty ring. On the 50mm AiS this is relatively straightforward with a rubber cone.

On the ‘E’ Series 50mm f1.8 these are very thin and very fragile. Too much pressure will cause the ring to distort outwards and jam.

If the beauty ring is stuck apply some Isoprop and wait. You may need repeated applications.

With the beauty ring removed this reveals the filter ring and front lens groups retainers. Note the filter ring screws sit on top of the filter ring while the cut outs sit over the front optic retaining screws.

On some Series E versions the lens retainers are countersunk underneath the filter ring so you will only see the filter ring screws.

First remove the filter ring. This is secured with three small screws. Use a JIS driver here to avoid damage to the screws heads.

Now remove the three JIS screws that secure the front element group.

The front element group can now be lifted off. Store this somewhere safe. Don’t bother cleaning it just yet. This lens can be a pig and you may end up doing multiple rebuilds.

This lens had very severe oil contamination. You can see the oil is present on the front lens group mounting plate and on the top of the focus helicoil. This is a typical issue. The internal glass has also hazed badly from oil vapour.

Now remove the focus barrel. This is retained by a thin metal retainer.

Before you remove this set the lens to infinity.

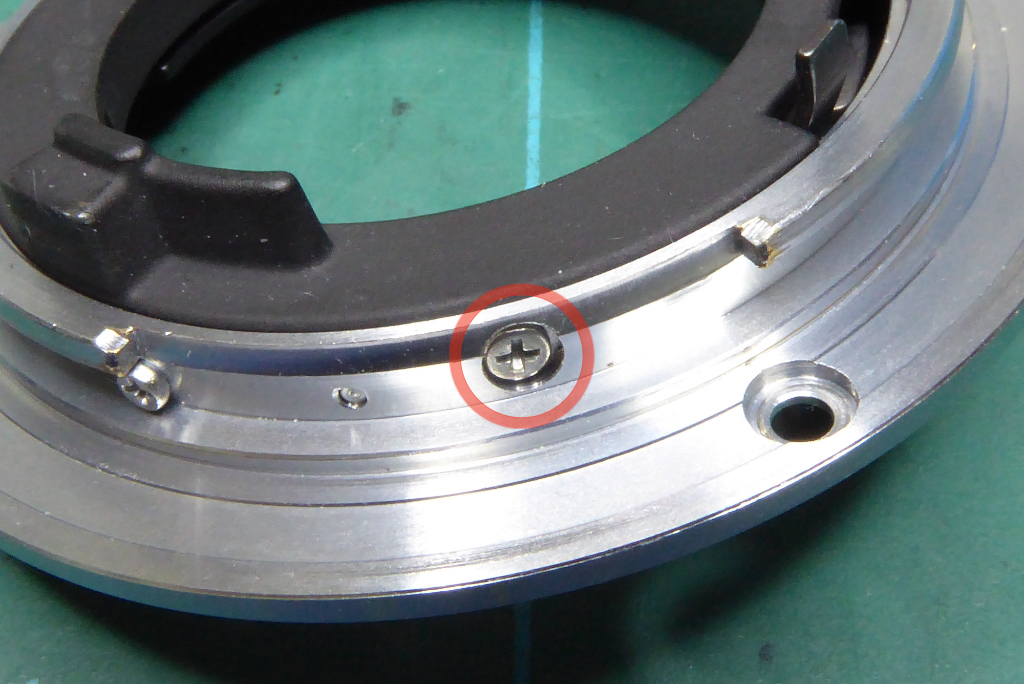

Note the relationship between the focus barrel retainer screws (RED CIRCLE) and the inner helicoil lobes (YELLOW ARROW).

These are critical on reassembly. Failure to get the relationship right will mean the lens focus will jam as you move towards back towards infinity as the lobes will catch on the focus barrel retainer ring.

Note the aperture control spring – this is discussed later in the guide – you need not worry about this if it is secured to its fittings.

And now the focus barrel can be removed together with its inner metal retaining ring. The retaining ring can be removed for cleaning but it is a very thin piece of metal so needs to be handled with care.

With the lens at infinity measure the distances between the helicoils (I usually use some very fine jewellers drivers to get an estimate of the width between the helicoils) and also put a mark on each helicoil and one on the lens body so you know where the zero point is for infinity….

This pic was taken a bit later in the process but it gives you an idea where you are marking

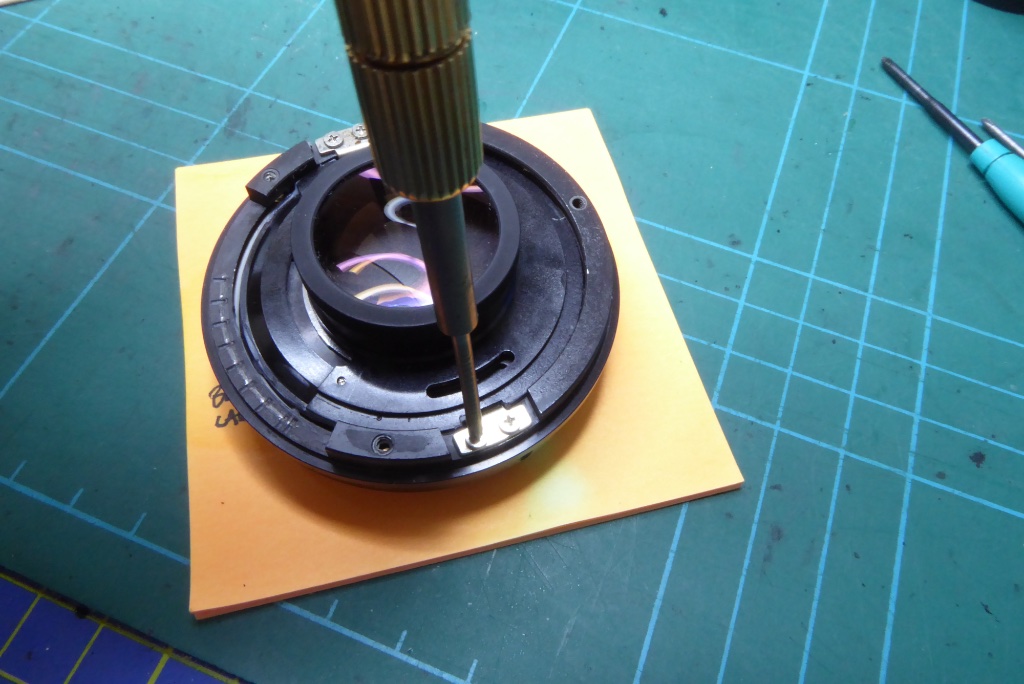

It’s now time to turn the lens over and start work on the rear of the lens.

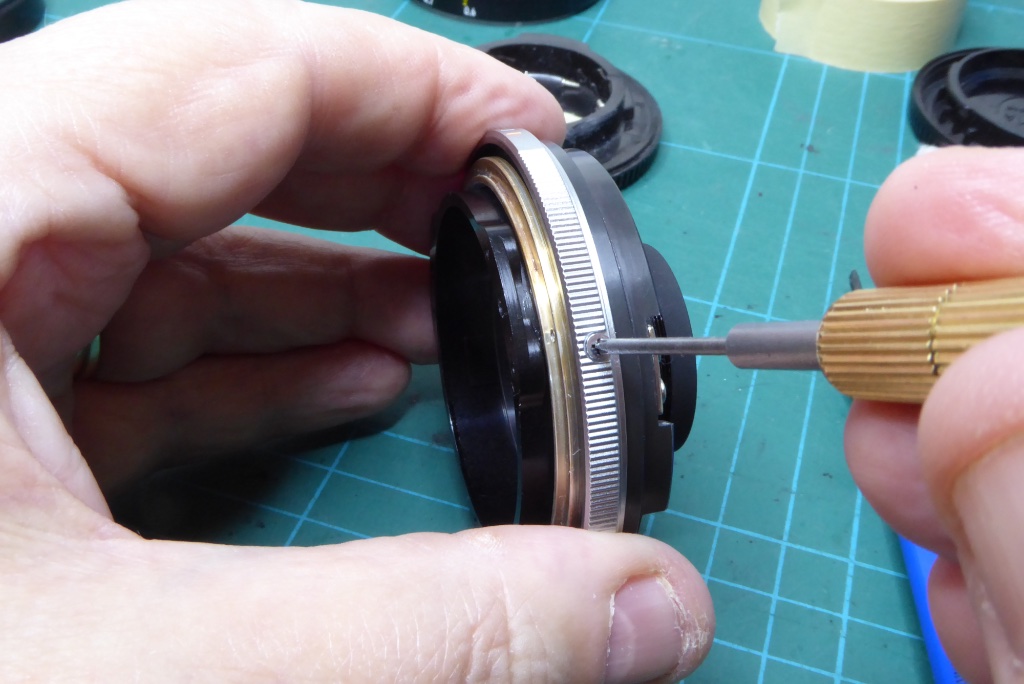

Remove the three JIS screws using a JIS screwdriver. These screws are usually VERY tight. Nikon loved the use of thread locker so if they don’t turn out easily apply some Isoprop and wait. A JIS driver is essential for these as they can be rounded out very easily.

The mount screws on this lens were particularly troublesome so I had to resort to extremes.

What you see here is the core of a high powered soldering iron (30W) applied to the screw heads. You need to do this until they are too hot to touch. This will melt the thread locker but you need to be VERY careful as the aperture ring is plastic. Mindfulness at all times!

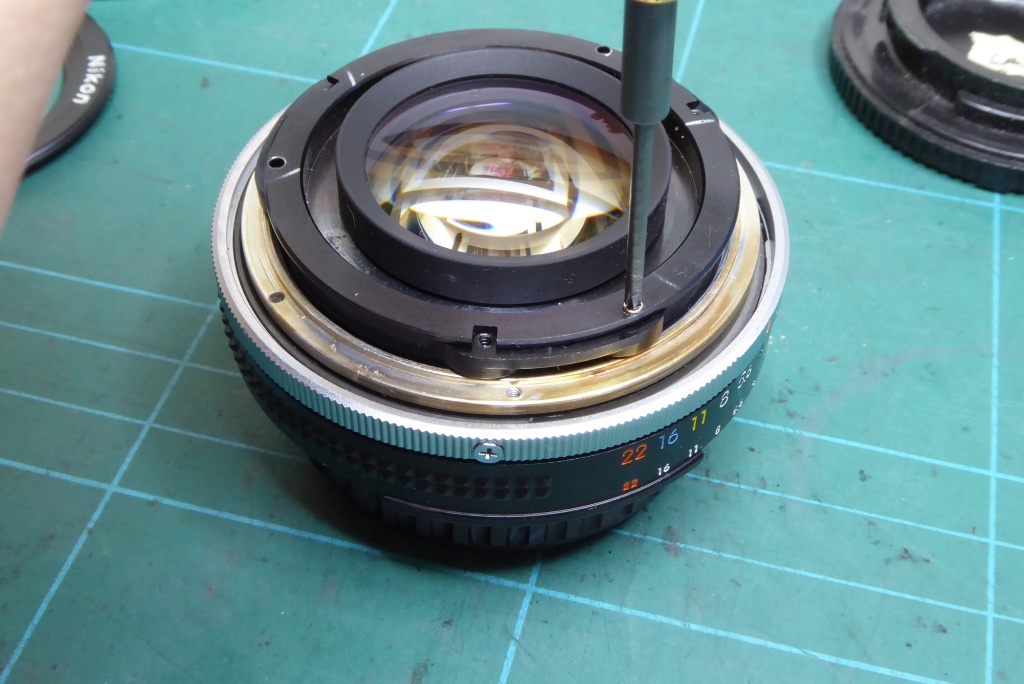

With the three screws removed the lens mount can be simply lifted off.

Note that the aperture lever on the mount engages with a slot on the lens body.

From this point on the lens must be supported by a cap at the rear as otherwise the rear optics will be in contact with any surface.

Take note of the orientation between the aperture lever (YELLOW) and the aperture slot for the mount (RED).

This is one of the less amusing aspects of this lens. The two aperture controls have to be aligned on reassembly together with the lock tabs AND the helicoils.

Lift the aperture ring off. Unlike many lenses there is no small bearing or spring to worry about.

Put a mark on the lens body where the black index mark is on the silver coloured ring. This should also be the mark you made for the focus at infinity

This will help you orientate it later when replacing it and also will help you reorientate the lens for mounting if you are forced to do a partial rebuild to get the infinity focus right.

You can see here a mark has been made both on the lens body and the helicoils for infinity focus.

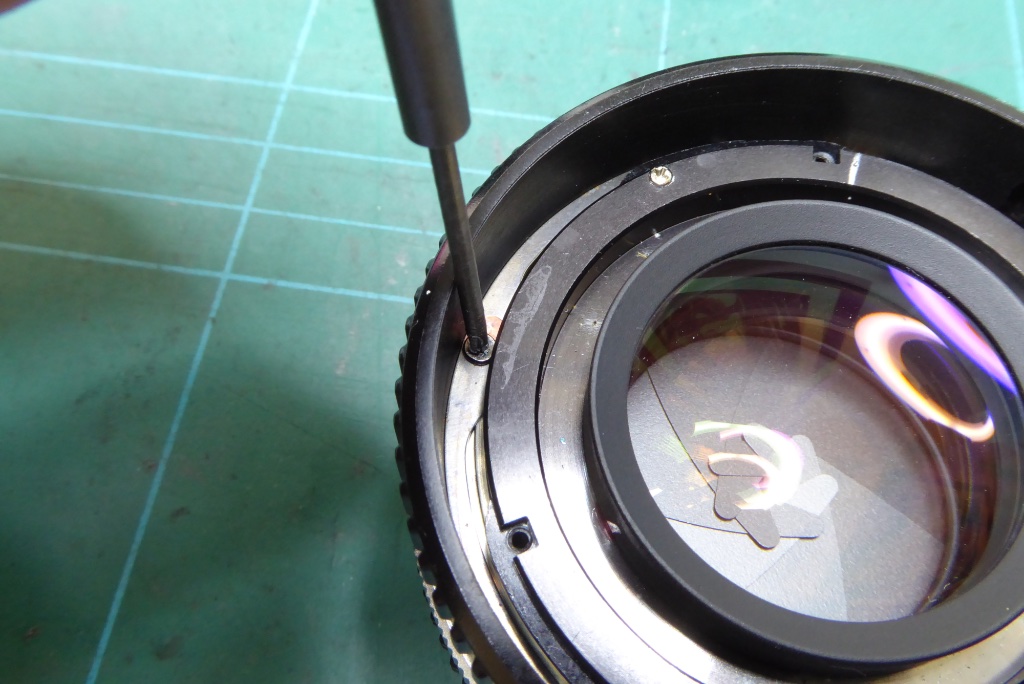

Remove the three screws around the silver index collar.

Remove the silver index collar.

Remove the focus lock tabs. There are two. One on either side.

These screws can be VERY tight and bonded with thread lock. Be careful with acetone or heat here as most of the core of the lens is plastic.

The two helicoils can now be unscrewed.

With this lens it is really critical to have these marked for infinity and also a mark where the helicoil separates so you know where the thread entry point is. It is well worth reading Richard Haws guide on working with helicoils HERE.

This is a shot from an earlier guide on the 1st generation Series E guide and shows the inner helicoil separation.

I didn’t get a shot of this lens but they look almost identical anyway.

And here’s the outer helicoil being removed from the lens body from the earlier guide. The lens body to the right is a little different but the basic principle is identical.

With the lens almost completely stripped you can now clean all of the lens body work.

Note that the rear element group, diaphragm and inner helicoil are all one piece. You are advised not to take this to pieces.

If you have fungus in the rear groups you can use acetone very sparingly to remove the rear group retainer but be very careful about spacers. You will also need a lens sucker to extract these and replace them. If the fungus is between lenses in the front group it’s a write off. The front group is a sealed group and cannot be disassembled.

The optics on this lens were ok and just needed the outer and inner facing glass to be cleaned. To remove oil I use a dilute Isoprop solution – 50/50 with water plus breath and a microfibre cloth.

Once fully cleaned the helicoils are lubricated with Helimax XP. As with most lenses you need to get the dosing right for the helicoil lubricant. Like many plastic bodies lenses this one needed a very tiny amount of lubricant on its outer helicoil metal/metal threads but a thicker dose on the metal/plastic threads.

The core of the lens contains the rear optics. Cleaning the old grease off of these is a careful job as this part contains the rear optics and the diaphragm. I normally use cotton wool balls to remove as much of the old lubricant as possible and then apply a dry toothbrush to get the remains of the old lubricants out of the threaded parts and then use more cotton wool balls. Once its close to clean I use a very lightly moistened cotton ball with some Isoprop to make sure its fully clean. You have to be VERY careful with this.

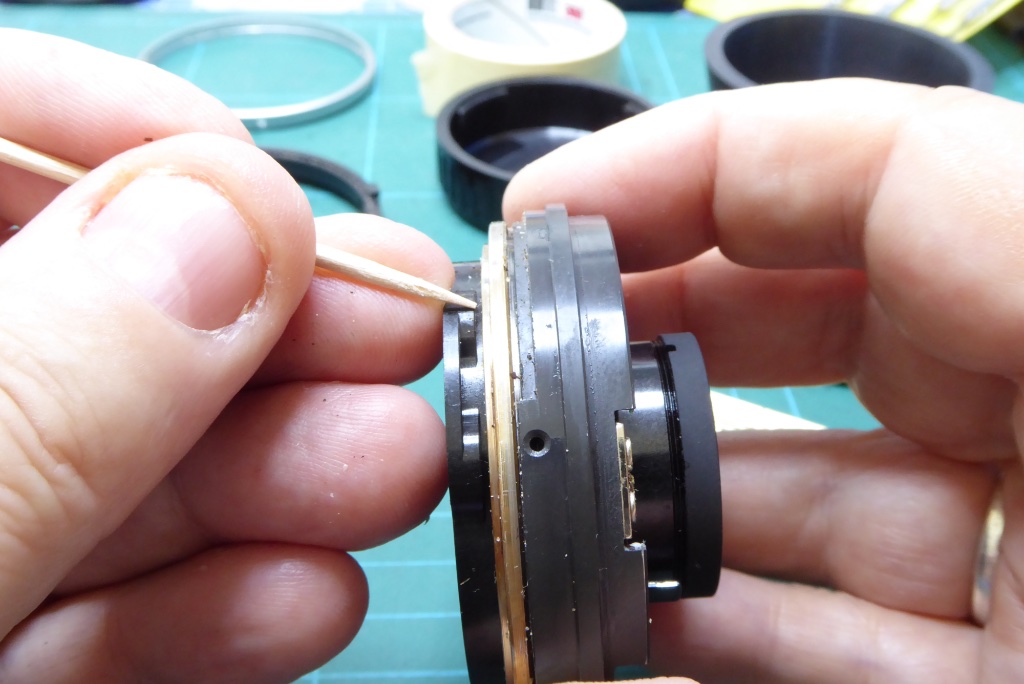

The other threads are cleaned out with alternate doses of hot soapy water and Isoprop and finally all threads are chased out with a cocktail stick to make sure the are completely free of contaminants like old dried lubricant.

All metal and plastic parts, with the exception of the lens core, are thoroughly cleaned of lubricants that had leaked. This includes the front face of the inner helicoil, the focus barrel and the mounting parts of the front optical assembly.

Do not clean the front optical unit inner surface until you are ready for final reassembly – you will see in the reassembly phase you may have to remove this a few times while setting the lens up so don’t clean its inner surface until you are sure all is working well.

Nikon 50mm Repair Guide f1.8 AiS – Reassembly

When reassembling do not over-tighten any screws. This lens can be a pig and you may end up disassembling. The name of the game is lightly tighten stuff down. Test the lens and if all is well go back and retighten screws after you are sure all is working well.

First lubricate lightly the outer helicoil and rethread it to the lens body. Assuming you marked the lens up appropriately earlier you need to find the thread entry point that allows the same distance to be achieved between the helicoil and the lens body AND the marks you made to align at infinity.

Now insert the inner helicoil using the same approach. The outer helicoils inner face has been given some lubricant but a bit extra is added to the threads on the inner helicoil.

Thread the inner helicoil into the outer helicoil using the marks you made to find the thread entry points and that the distance is the same as when you took it apart and the marks you made earlier align.

Like the Series E the AiS version is no fun. Nikon designers could be cruel! As well as the helicoil distances you have to meet the following as well.

The inner helicoil must align with the lock tab positions and…..

….The relationship of the aperture lever must be as pictured. The aperture lever has to be to aligned so that the lever is at the 6 o clock position while the mount aperture connector is at the 3-c-clock position and…

(Note this pic was taken a bit later – its only to show the relative positions of the aperture, lock tabs and detent slots for the aperture control ring.)

…The detents for the aperture ring are also in the right position alongside the aperture lever on the lens body. It’s not as hard as it sounds but you need to be aware of this now before you commence reassembly. Apply a light smear of lubricant to the detents – just a small smudge is enough.

Once you are happy that all is well and alignment of the interior parts is correct and the helicoil distances are in close approximation to what you measured before disassembly you can replace the focus lock tabs. Do not over-tighten just yet- you may need to make changes later.

Replace the silver ring using the mark you made earlier and replace the three screws.

If for any reason you couldn’t or didn’t mark the helicoils for infinity its best to leave this ring off for now and come back and add it later. Without this ring it’s much easier to grip on the outer focusing helicoil when testing. The mark on the lens body will help you sort out orientating the lens to the camera mount.

Replace the aperture control ring making sure it goes OVER the aperture lever on the lens body.

It needs to be put on by placing it vertically downwards NOT from the side.

Replace the mounting ring making sure the aperture lever on the mount ring locates into the slot on the lens body.

Replace the front optical unit after suitable cleaning. I use a mild Isoprop solution and then breath with a microfibre cloth and a final blow out with a rocket blower.

Note the fittings on the optical unit carrier. The holes are for the lens retaining screws while the slots are for the filter ring.

Replace the three screws that retain the front optic.

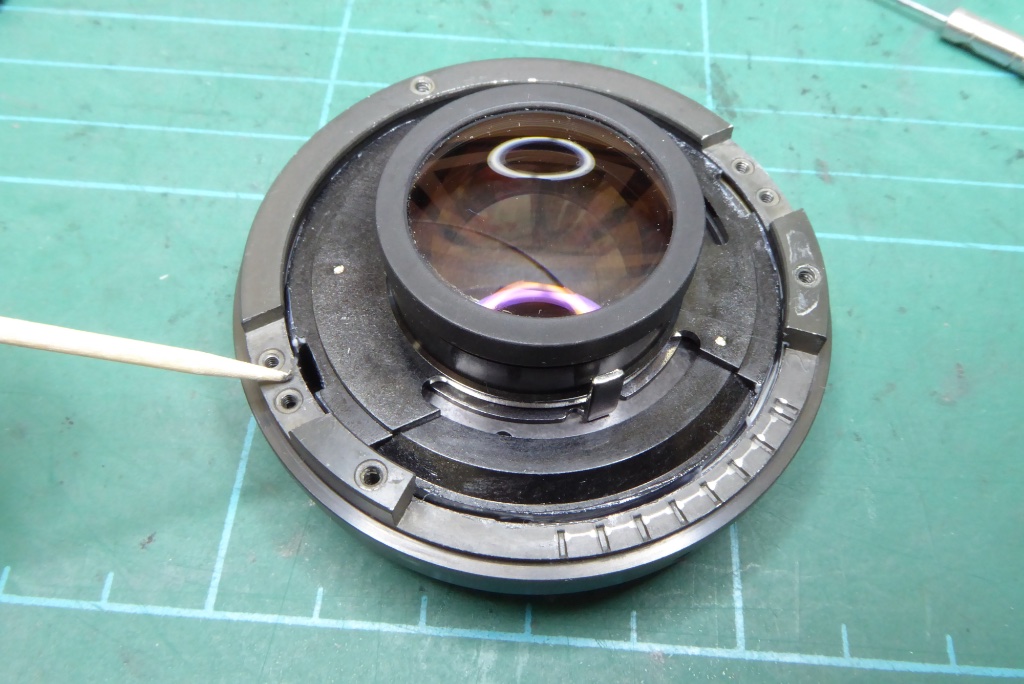

Note the brass outer helicoil…..

You can now mount the lens as it is on a known camera and using the brass outer helicoil get focus on a distant object. I usually use two radio towers which are around 8 miles distant. I can use a collimator but this only works well if you have a reference lens.

Heres the lens mounted on a trusted and reliable F-301.

The focus barrel is now placed over the lens with the infinity mark aligned to the index mark and lightly secured with its three screws for a final test.

If testing is good and the lens operates freely from end to end of focus throw the focus barrel can be secured.

Bear in mind a lot of this lens is plastic so don’t go mad on tightening stuff. Safest method is to use the small JIS driver between thumb and forefinger and tighten using just your thumb and forefinger. When it feels tight thats tight enough.

If the focus jams then chances are you have not enough space underneath the lobes of the inner helicoil OR positioning is in some other way incorrect. In which case your only option is to rebuild.

If for any reason you were unable to make markings for thread entry points or infinity focus you may end up reworking the lens. I have had one where the focus was jammed so it was not possible to get useful markings.

With the focus barrel on you now only need to add the filter ring and…

Replace the beauty ring using a rubber cup.

Notes on the Aperture Control Spring

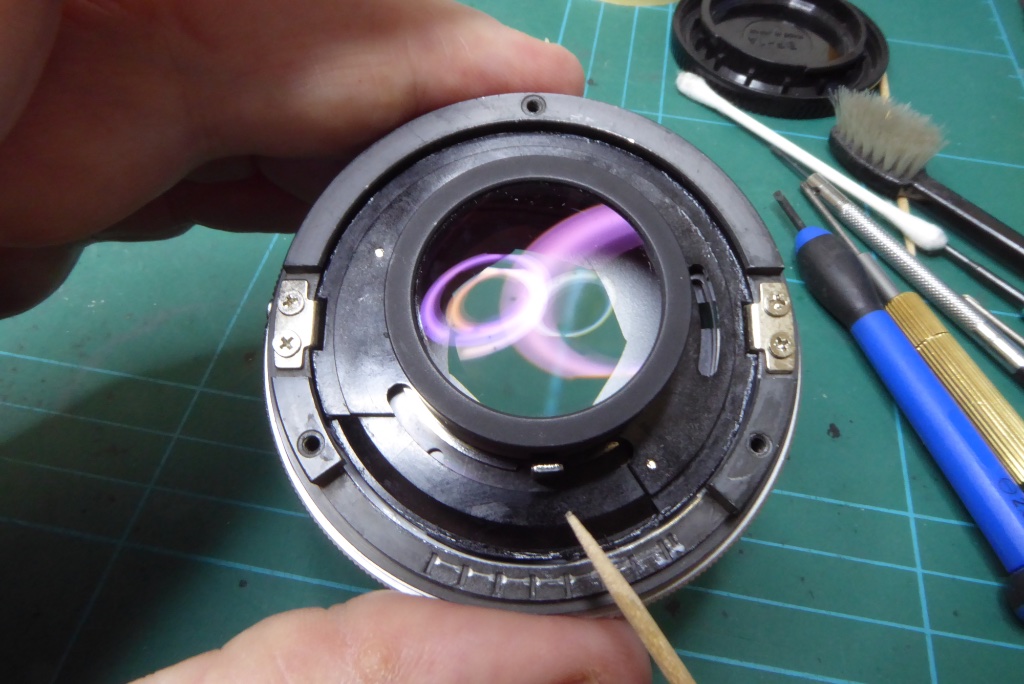

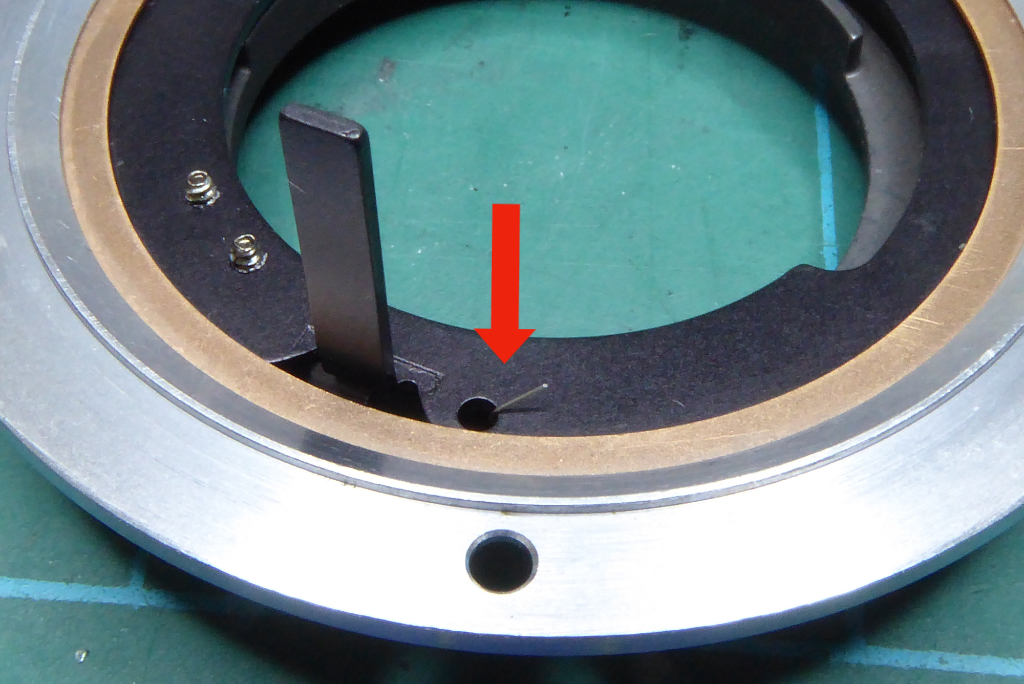

You will have seen earlier that the aperture mechanism uses a spring on the front face of the diaphragm BUT… the real power in the aperture control is the spring located in the mount assembly. If you have a very slack diaphragm the chances are it’s the spring in the mounting plate. On the inside of the lens mounting plate you can see a small spring is hooked over the hole near the aperture lever. This can come free if while cleaning you have dislodged it.

To reconnect the spring you need to remove the three recessed screws around the edge of the mount plate. Ignore the screw that stands proud of the rim and just remove the three recessed screws.

With a little bit of wriggle the inner black part of the mounting will come free allowing you access to the spring. When replacing be aware of the slot that allows the camera side aperture lever to move.

Here’s the spring with its fixing. It’s end simply loops into the hole.

DO NOT remove the screws on the aperture lever – these are fine tuned by the factory for the aperture and are very much best left alone.

Mount the lens for a final check, check infinity and focus throw and also make sure the lens stop down is working correctly.

Thats it – I will wish you all the best of luck with this lens – it can be a complete perisher.

It is a superb lens when clean and operating well and I hope this guide will have allowed you to return this lens to pristine condition.

This Nikon 50mm Repair Guide article can always be improved. If you have any questions and or comments we would love to hear them below. Mel.

Further Reading

Mel is one of the driving forces behind High 5 Cameras and writes all our articles.

Starting serious photography back in 1972. Over the years she got to shoot film with most of the major brands in 35mm and large format as both a studio photographer and content provider for websites in the early life of the web. These days she is rediscovering photography and has become the GOTO person for knowledge on camera repair advice.